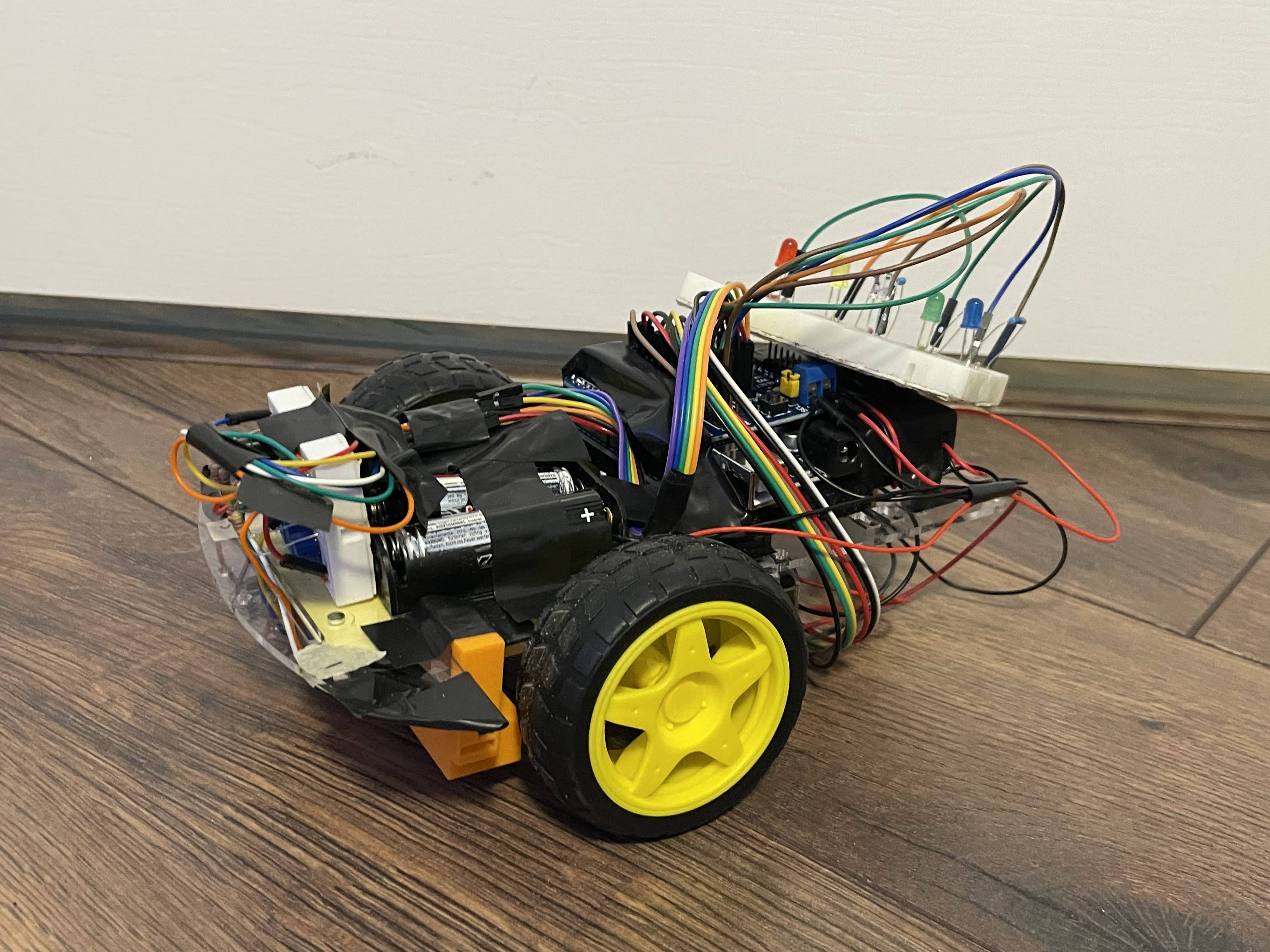

Autonomous Line-Following Robot

September 2022 - November 2022

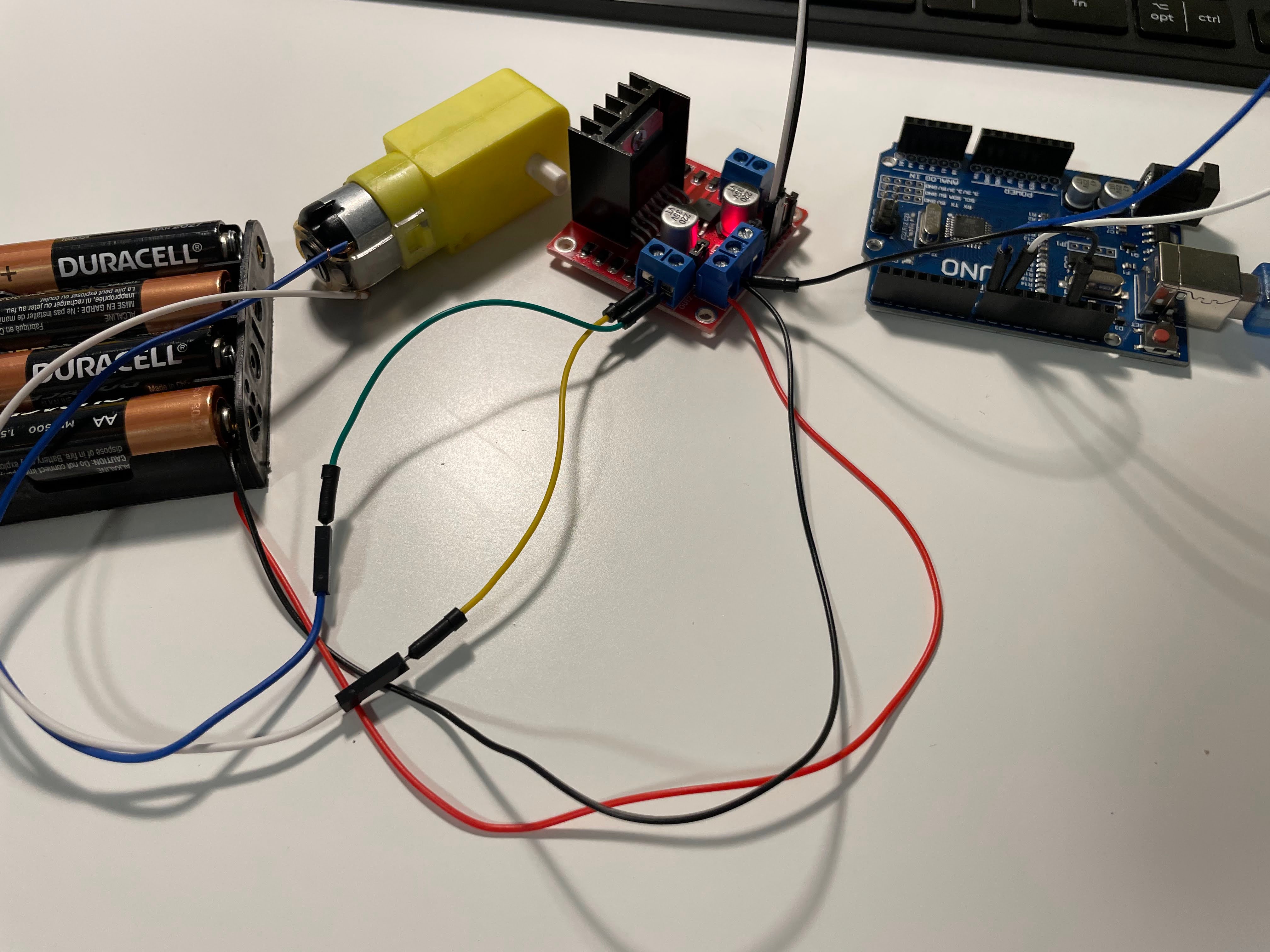

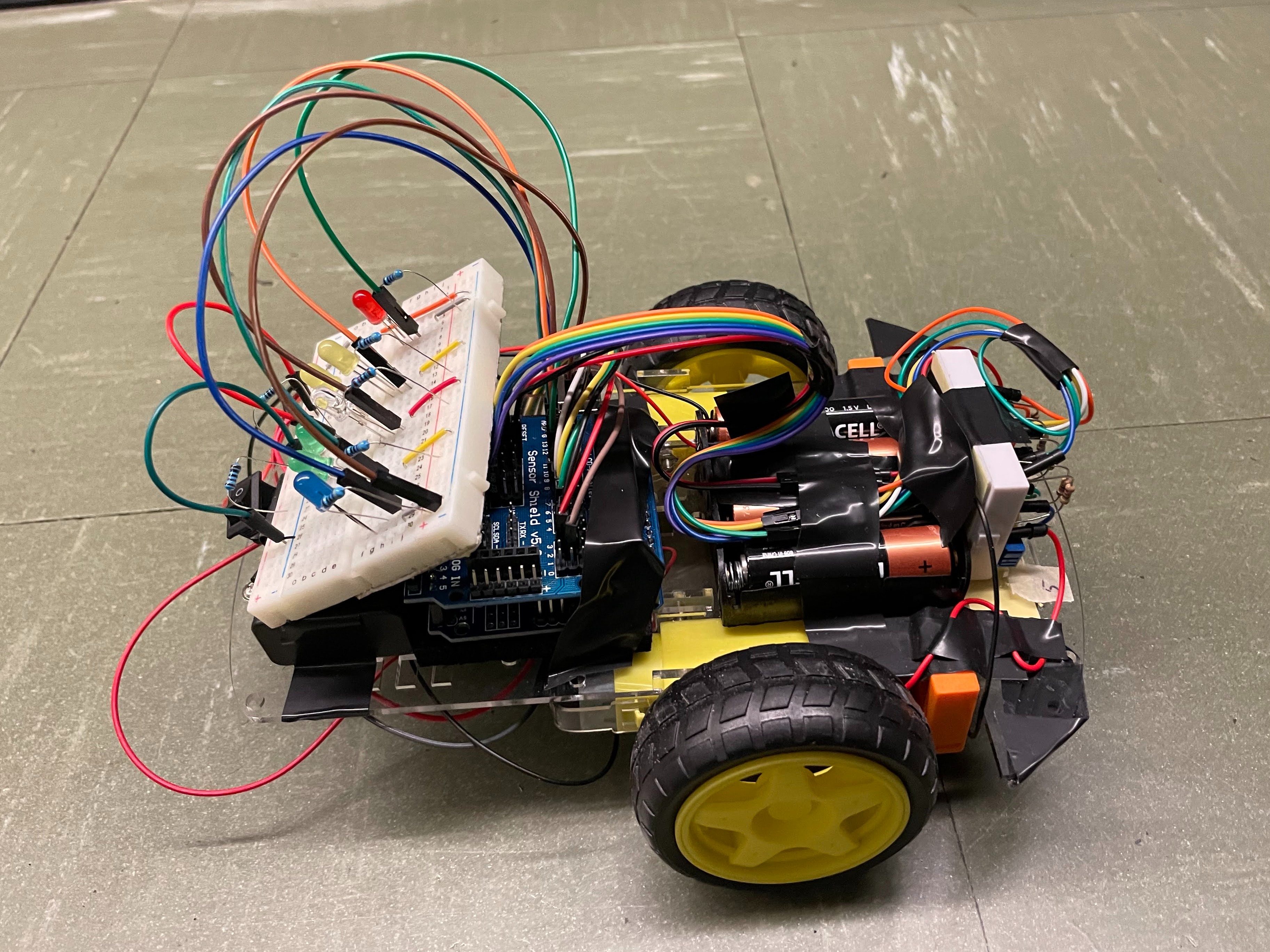

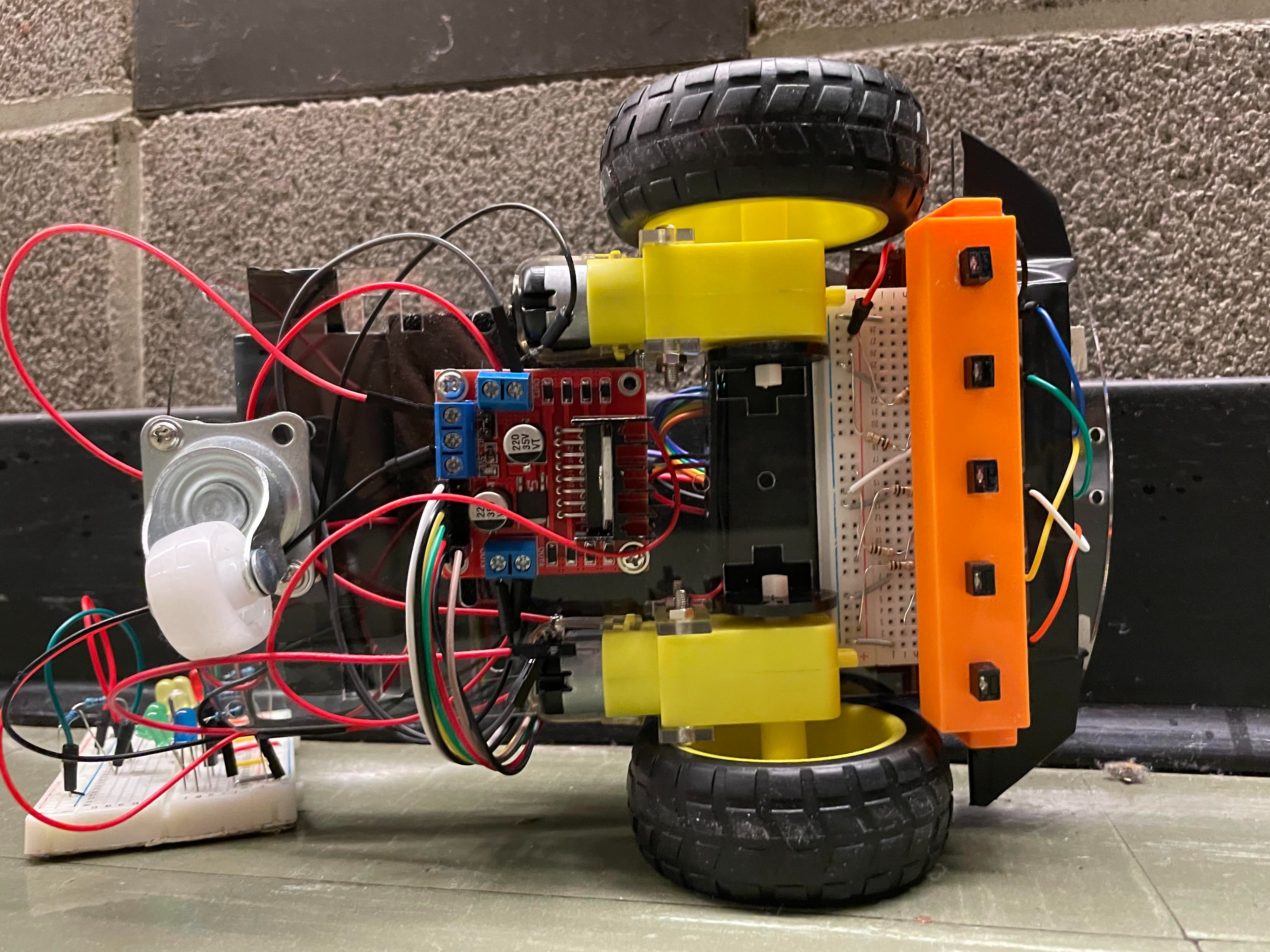

This robot was created for my IGEN 230 course at UBC. It consisted of chassis parts, phototransistors, an Arduino Uno, and other relevant parts.

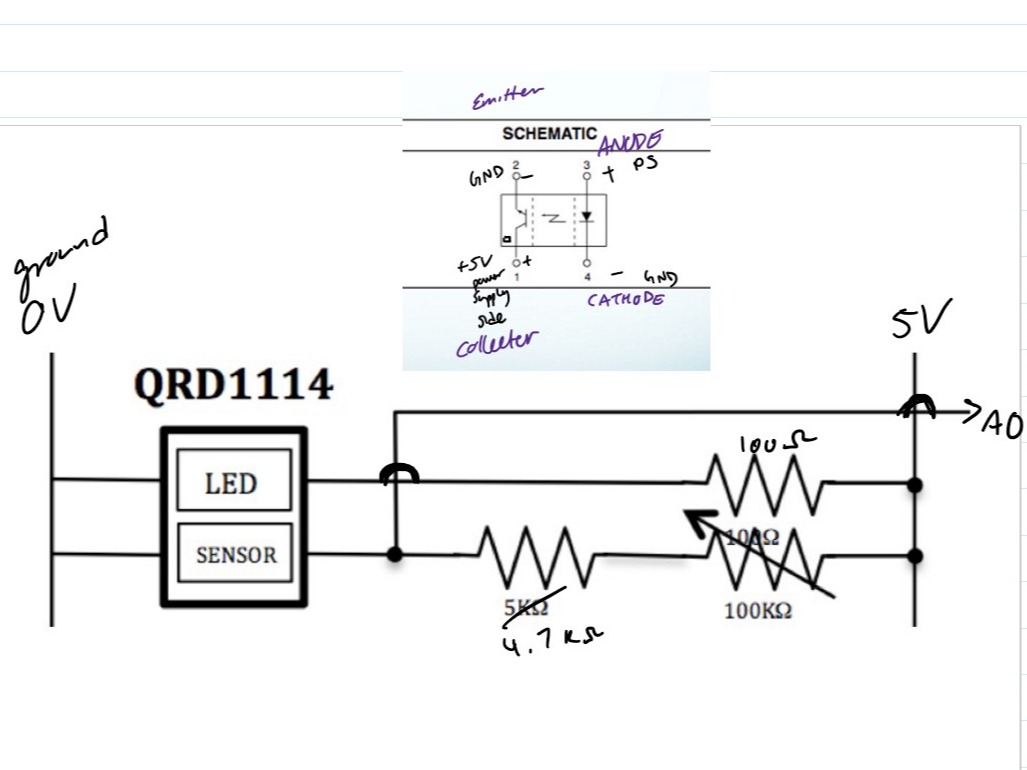

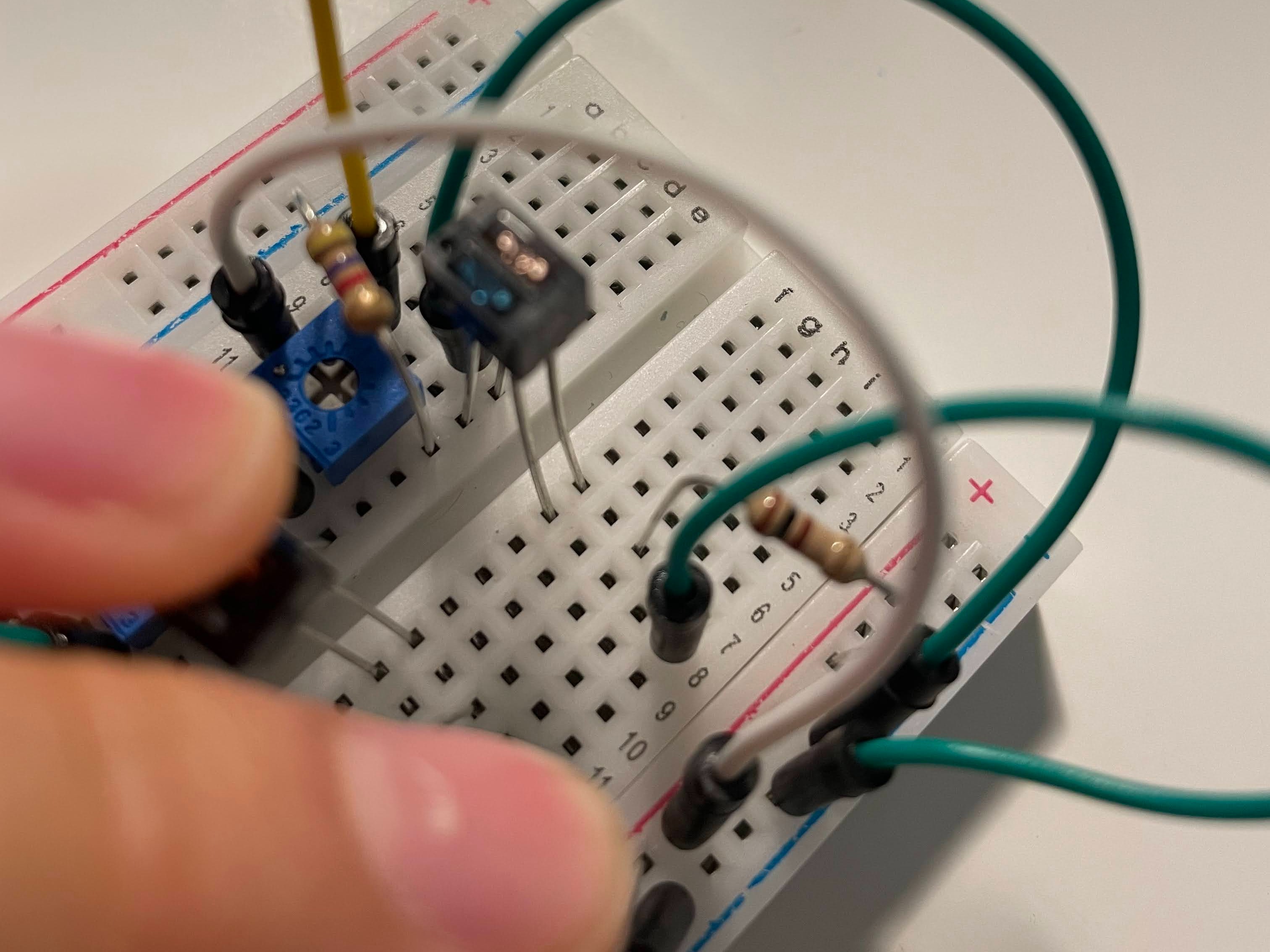

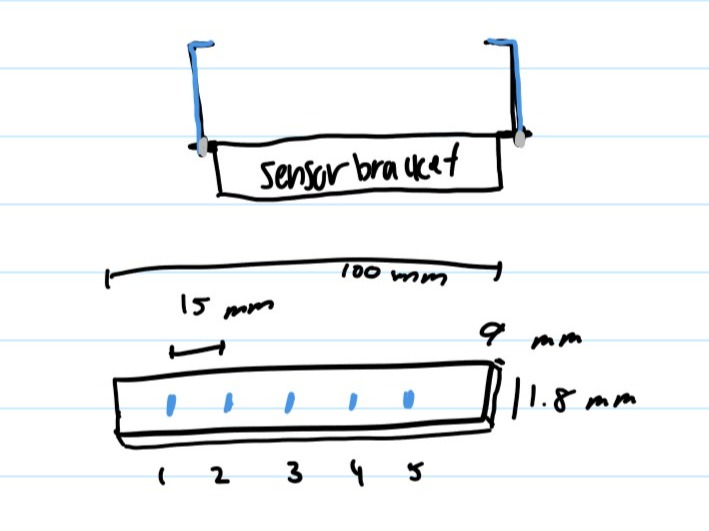

The use of infrared reflective sensors (phototransistors) allowed for the robot to detect the presence of dark lines. An Arduino Uno powered the robot running on a code that I wrote, based off the example our professor provided us.