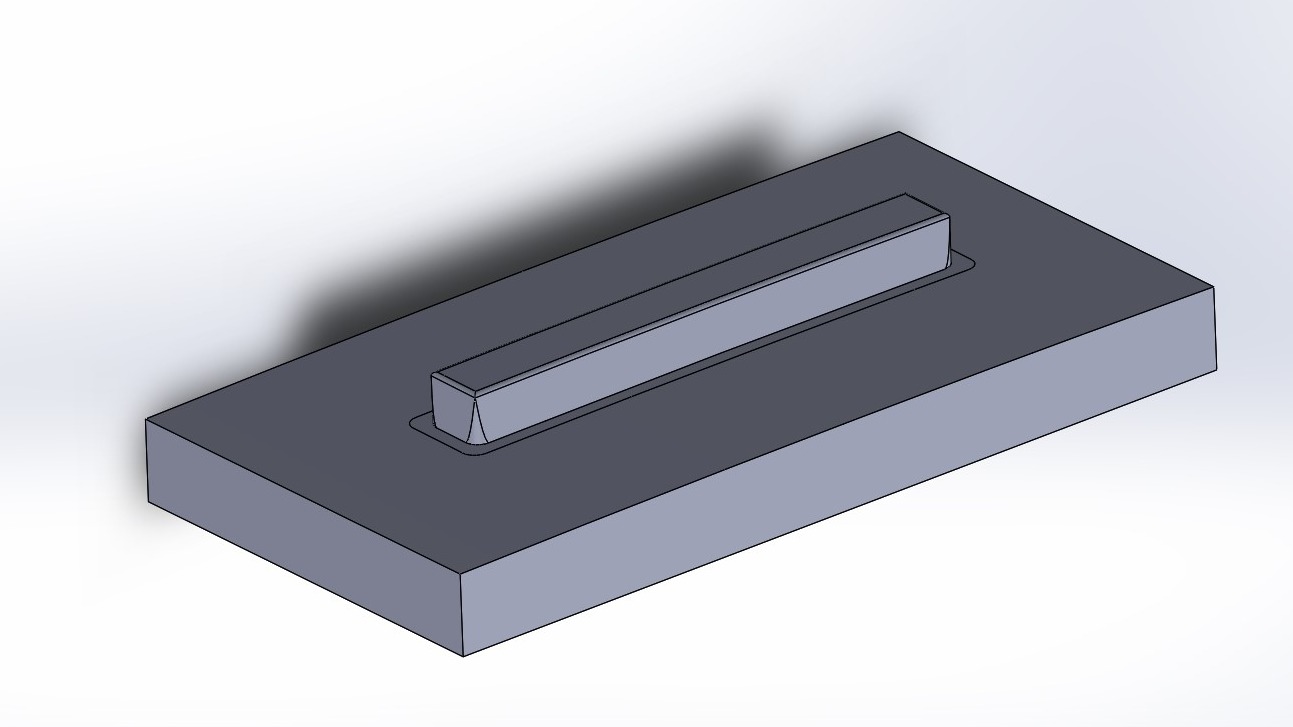

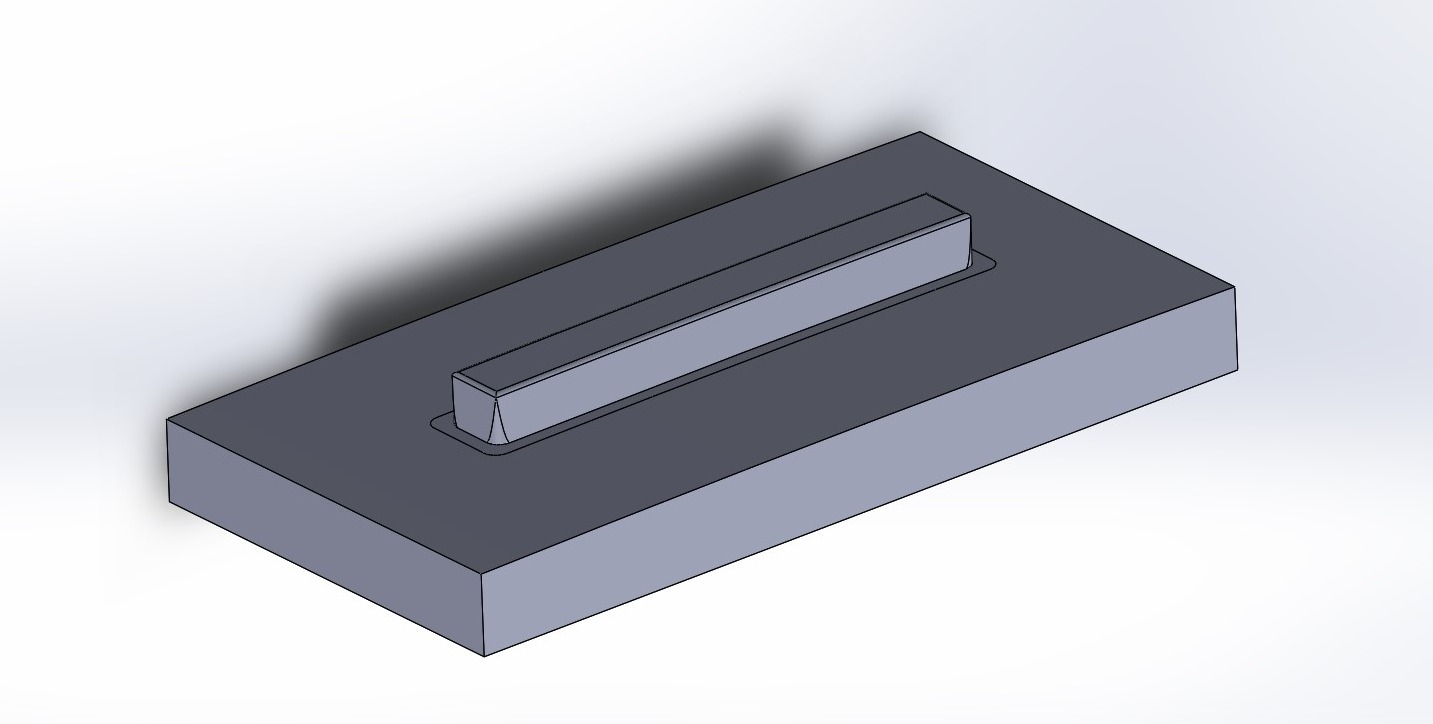

Thermoformed Light Cover

September 2022 - October 2023

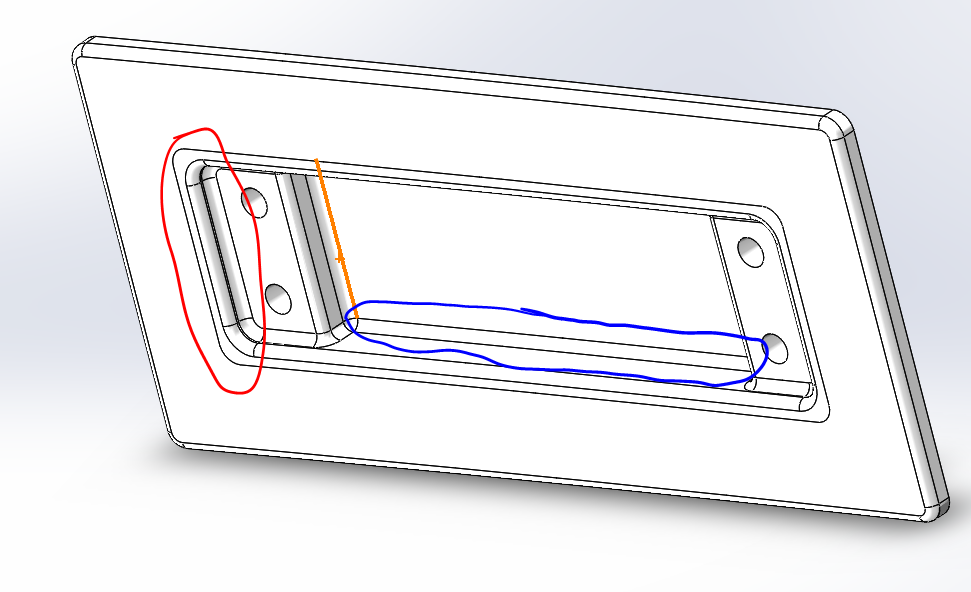

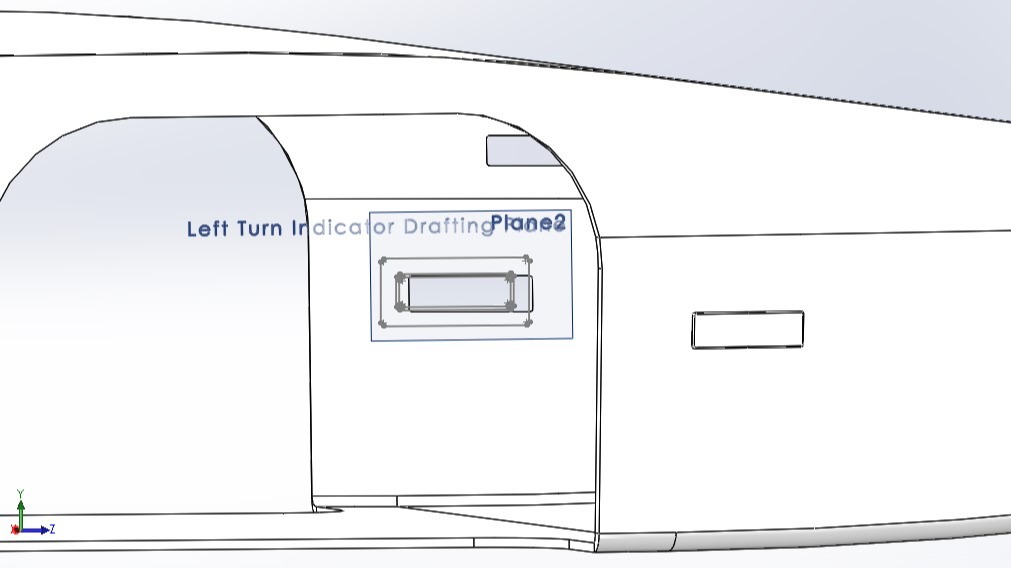

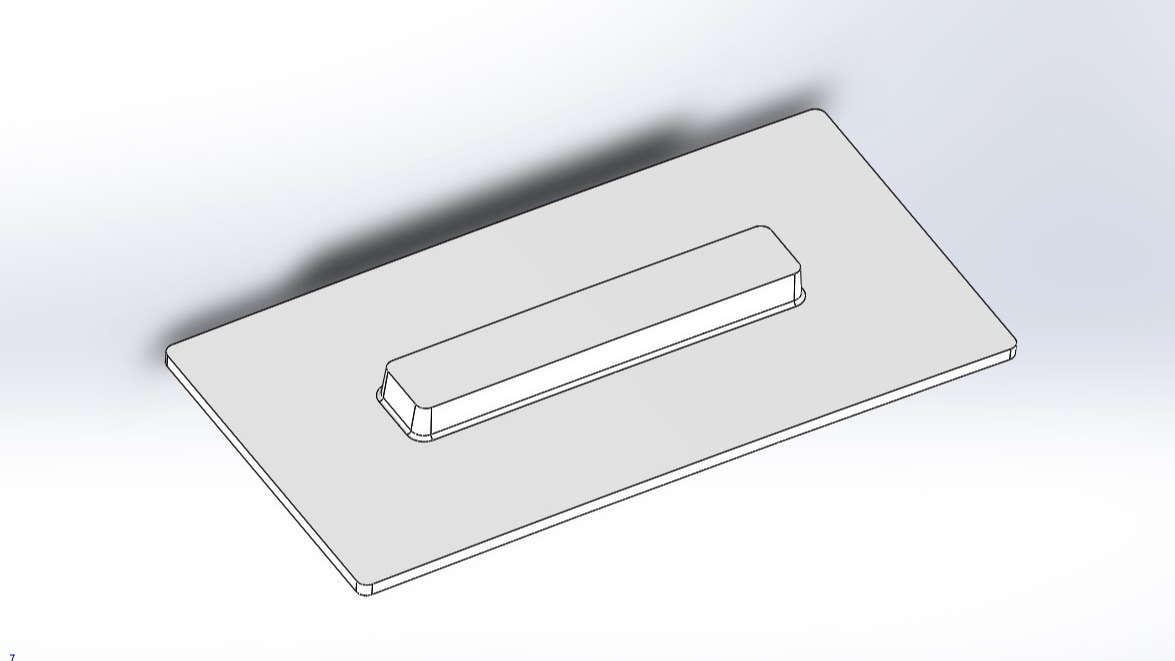

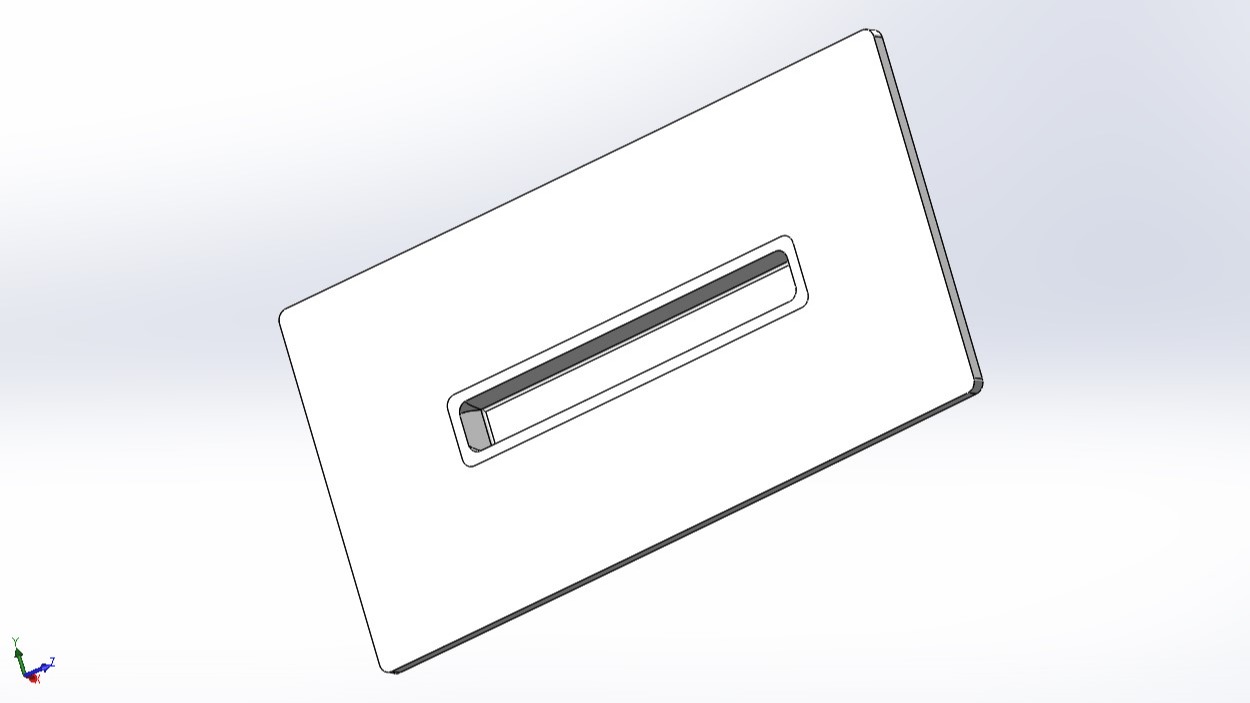

An ongoing project designed for UBC Solar — a design team of which I have been a part of since my 1st year. These light covers are intended to shield the side light indicators and front lights from debris and other damage.